The plumbing system is designed to regulate, direct, and distribute all kinds of liquid. The valve is an essential part of it. This has made the selection of correct valves a crucial part of any kind of application, from household to industrial systems. To ensure the safety and efficient operation of valve performance, it is essential to choose the correct valve. PlumbingSell offers a wide range of valve selection for you to choose from. Learn more about the fundamentals of valve selection vital before you make any decision related to the valve.

In this article, we will cover some practical factors to consider when choosing the right valve and how to identify the right valve for various applications. This guide provides the basic knowledge for every consumer who needs to be more confident about choosing the perfect valve.

Table of Contents

Valve Type/Key Functionality

Understanding the purpose of the valve and the medium that will go through it is essential as a starting point. Identifying the service medium and function requirements are the most important factors to consider. The selection of a valve is not a choice guided by your preference; rather, it is mainly based on the valve’s capability to meet some specific operating conditions.

By specifying the performance requirements of the valves that are going to be installed in the system, you can compare these with different kinds of valve types to find out the right one. The purpose of the valve usually is our top priority when choosing the valve. The medium that goes through the valve is as important as the purpose. The toxicity of fluids or any kind of corrosive properties, or sanitary requirements for the plumbing system will influence your choice of valves.

Here are some common questions that could help you find out the purpose and medium of the valve:

- What is the valve’s main purpose? (e.g., shut-off, flow control, pressure regulation)

- Does the valve need to fully open and close, or should it regulate flow?

- Does the valve need to be manual or automated?

- Does the valve need to prevent backflow?

- Does the system require quick opening/closing, or is a slow transition preferred

- Is the medium corrosive, abrasive, or hazardous?

- Is the medium clean, or does it contain solids or debris? (This can affect clogging and maintenance)

- Is the medium flammable or explosive?

You could use these questions as an essential guide to help you decide the potential types of valves for your design. To find out more about the specific introduction of different kinds of valves, check out more from our introduction to valves.

Material

When choosing a valve, material is another important consideration, as it has a direct impact on the valve’s durability, safety, and compatibility with the system. To decide what kind of material is suitable for your system, you first need to understand more about the medium that will go through the valve. Ask yourself these questions to identify the properties of the medium:

- What fluid is going through the valve?

- Does the valve need to be corrosion-resistant?

- What is the fluid temperature and pressure range?

- Is the fluid being treated before it reaches the valve?

- What are the safety requirements of the valve?

Answering these questions will help you narrow down your valve selection one step further by determining the materials required for the valve. Proper material selection helps ensure the performance and durability of the valves. Below are the notable properties of some common valve materials.

- PVC (plastics) – mainly used for low-pressure systems, resistant to corrosion and erosion.

- CPVC (chlorinated PVC) – similar to PVC, it is more resistant to high-temperature applications.

- Brass and bronze – corrosion resistant, ideal for both water and air.

- Stainless steel – highly corrosion resistant, durable, and suitable for both high-pressure and high-temperature applications.

Choosing the right valve material is crucial for the valve’s durability and safety. The fluid property, pressure, and temperature will mainly decide the material used. The wrong material could cause potential leaks or damage, leading to a higher maintenance requirement and shorter lifespan.

Valve Size

The valve size is also important for the selection. The desired flow capacity and the flow rate of the water of the requirements of the plumbing system dictate it. Just like other factors, there are no strict limitations on how to determine the best valve size. Understanding the system requirements is the key. Before selecting a valve size, try finding out the key information about the system you are designing for. Such as the flow rate, operating pressure, and pressure drops.

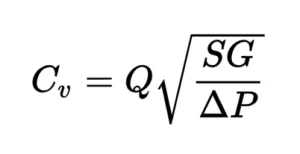

Manufacturers typically provide a flow coefficient (Cv) figure. It is a measurement that shows how much fluid can pass through a valve at a given pressure drop. This figure indicates the valve’s capacity to allow flow to go through. It is the key figure for choosing the right valve size for a system. If not provided, here’s a formula you could use to calculate the Cv.

Q = Flow rate (GPM)

SG = Specific gravity of the fluid (water = 1)

ΔP = Pressure drop across the valve (psi)

The selection of the correct valve size is essential, as an improperly sized valve could cause operation issues within the valve and the whole system. A small size valve will restrict the flow, causing pressure drops that lead to reduced efficiency and potential damage to piping. On the other hand, a valve that is too large could make the operation unstable because of the poor control of the valve. Proper sizing ensures smooth flow, maximizes the efficiency of the valve, and ensures the durability of both the valve and the plumbing system.

If you are not sure about the valve size, feel free to reach out to us for help.

Conclusion

Selecting the correct valve is a crucial part of any plumbing system. Having a proper valve chosen will help with flow control, ensure smooth operation in the system, and minimize energy loss. Choosing the right valve is not just about selecting the right sizes; it is more about ensuring the safe, efficient, and cost-effective operation of the whole system. Although it would take time to conduct the evaluation to choose the right valve, it will help prevent issues and minimize future maintenance requirements. Discover more on our valve options here.