What type of materials could you use for your plumbing system? When working on a plumbing project, it is crucial to select the right kinds of fittings for each unique system. Plumbing pipes and fittings are generally produced out of PEX, PVC, copper, iron, brass and copper. Usually, we would go with the ones that could ensure durability, performance, and, ideally, budget-friendly. However, it is noticeable that not all materials work well together.

If incompatible types of fittings are used in one plumbing system, potential issues could occur. For example, if you use brass pipe fittings together with stainless steel ones, galvanic corrosion could occur. This comprehensive guide from PlumbingSell will address the concerns of using mixed materials in one plumbing system by providing details on how to use copper fittings and brass fittings together.

Table of Contents

Understand Brass & Copper fittings

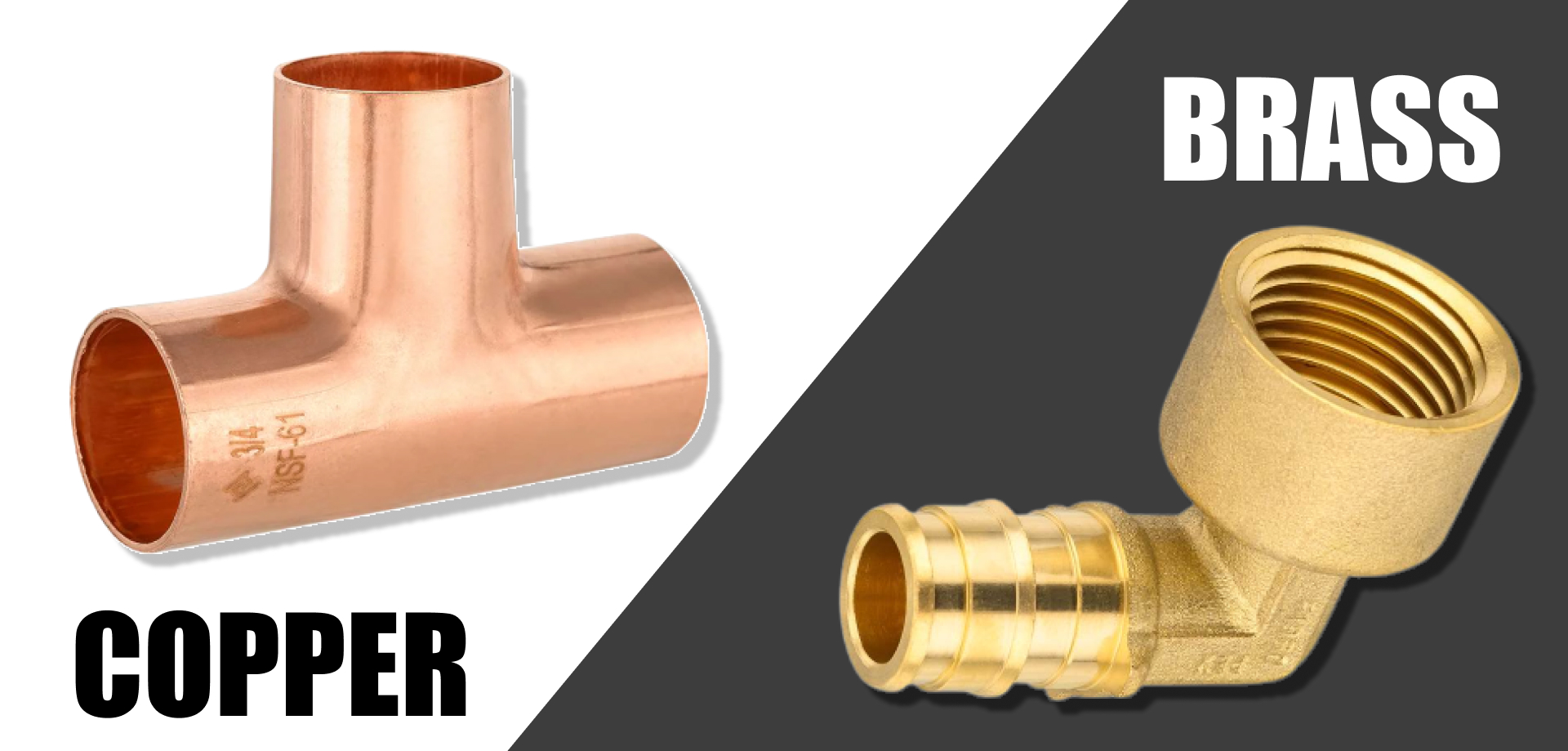

Brass and copper are two of the most popular materials in modern plumbing systems. They are both known for their durability, corrosion resistance, and versatility. Although they share some common characteristics, each has unique properties and limitations that make both brass fittings and copper fittings suitable for a wide range of applications.

Copper Fittings

Copper is a natural metal well known for its exceptional durability, resistance to corrosion, and ability to safeguard water from contaminants. As a long-lasting and reliable material, copper is widely used in both residential and commercial plumbing applications. Copper pipes and fittings are vital for plumbing systems; however, due to their complexity of manufacturing, there are not many shapes available.

Copper pipes and fittings are mainly used for hot and cold water systems, heating systems, and gas lines. They are typically used to create tight, secure, and long-lasting connections between pipes. They provide the flexibility and security required for efficient plumbing installation, which has made them one of the top choices for both professional plumbers and DIY lovers.

Brass Fittings

Brass is an excellent metallic alloy widely used in plumbing applications. It is known for its durability, resistance to corrosion, and cost-effectiveness. Brass mainly consists of roughly 60-70% copper and 30-40% zinc. A wide range of brass pipes and fittings is available based on different needs.

Brass pipe and fittings are popular among plumbers because of their significant durability and flexibility compared with other material options. Brass pipes are generally used for carrying most types of fluid, from water to flammable gasses and more. While the brass pipe fittings have an even greater range of selection, they come in various shapes and sizes that make them suitable for most applications for both residential and commercial plumbing projects.

Difference Between Brass & Copper fittings

Although brass and copper share many similarities, such as being durable and resistant to corrosion, it is still important to be aware of their differences. Learning about these differences will help you decide which is best for any projects you are working on.

The primary differences between brass fittings and copper fittings are their composition, properties, and applications. We’ll explain in more detail below.

Composition

As you might know, copper is made from pure natural copper, whereas brass is considered a copper alloy, meaning it is composed of both copper and zinc. This composition difference has given them different appearances. Copper fittings are typically reddish-brown to coppery orange, while brass fittings are typically yellowish-gold.

Properties

Corrosion resistance is an important property to consider when selecting the plumbing fittings material. Although both materials have a relatively high level of corrosion resistance, brass fittings are normally not as effective as pure copper fittings.

Both copper and brass fittings are durable and strong, but copper is not as strong as brass. If you are looking for pipe fittings that can endure high pressure or physical stress, brass fittings will be your go-to choice. However, if you are looking for fittings that are easier to install in tight spaces or around obstacles, go with copper pipe fittings. They are more flexible and less likely to crack when bent.

Applications

Copper fittings are an essential type of material in various applications and are often used in systems that require high conductivity and resistance to corrosion. For instance, you may have seen copper fittings in water supply lines, heating systems, or gas lines. Copper pipe fittings’ resistance to corrosion and hot and cold water have made them the ideal option for these applications.

Brass fittings are more often used in valves, faucets, pumps, and other mechanical applications than copper fittings. Because brass is composed of copper and zinc, it tends to be harder and more durable than pure copper. This has made it the better option for applications with high pressure or environments that require durability.

Can you mix copper and brass fittings

The short answer is yes, copper fittings and brass fittings can be used together. From the material-wise aspect, copper and brass are compatible in their physical properties. As we mentioned before, brass is an alloy of copper and zinc, which makes it share a lot of common features with copper. This has made copper fittings and brass fittings compatible for connections. However, there are still some important factors to notice when you are trying to use the two different materials together.

Brass fittings are typically used for copper pipes when other piping materials like PEX are requested to connect to them. Take a brass compression fitting as an example. They are widely used because of its excellent strength, durability, and resistance to corrosion. By using brass pipe fittings with copper pipe fittings, the rigid brass and flexible copper could help elevate the durability and adaptivity of the entire system.

Both brass and copper are considered highly corrosion-resistant. However, galvanic corrosion can still happen. Although brass and copper are considered similar metals, they still have some dissimilarities. And when two different metals come into electrical contact in the presence of water or even moisture, dissimilar metal corrosion (galvanic corrosion) happens. If this ever happens, one metal will likely corrode more rapidly than the other.

Galvanic corrosion can cause a potential leakage in the system, so it must be considered when choosing the proper material for your project. One practical way to avoid this is to keep the two materials away from each other. For example, you could connect a pex and copper fitting on one end of the pex pipe and then a brass fitting on the other end.

Conclusion

Copper pipe fittings and brass copper fittings can be used together in plumbing systems. In fact, they are commonly seen together in pipe design. For example, brass threads could be soldered on a copper pipe. The two materials share many similarities: They are durable, corrosion-resistant, and versatile. However, it is still essential to understand their differences and consider them when choosing the suitable material for your project.

Although it is perfectly fine to use copper and brass fittings together, there are still chances for galvanic corrosion under certain circumstances. So choose the fittings wisely, install them correctly,, and figure out the specific needs of your plumbing project. If you have any further concerns about how to pick the right pipe fitting for your project, feel free to get in touch with us.