PEX (cross-linked polyethylene) is a commonly used type of pipe in modern plumbing. It has revolutionized the industry with its flexibility, durability, and ease of installation.

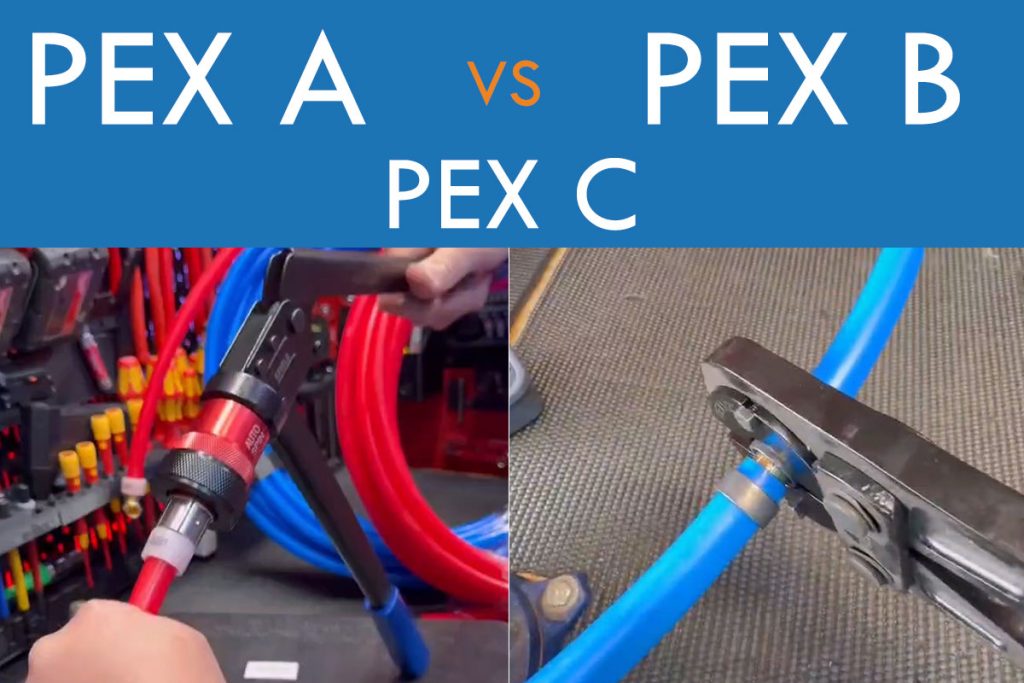

You might have already noticed that PEX-A, PEX-B, and PEX-C are available on the marketplace, but you are not sure what the differences are among the three types and which one is best for you. In general, the letters are used to identify the three types of PEX manufacturing processes; they don’t relate to any quality or performance rating.

Below, we have outlined the main features of all three kinds of PEX pipes, their differences and similarities, and a guide for you to decide which one to choose for your project.

Table of Contents

What to know about PEX-A

PEX-A pipes are produced using the Engel method (also known as the peroxide method), named after Tomas Engel, the inventor of this method. The process mainly consists of four stages: raw material selection, extrusion, cross-linking, cooling, and sizing.

One of the main differences of PEX-A pipe is its high degree of cross-linking, which results from the manufacturing process. When HDPE polymer is melted, free radicals are created, and a chemical reaction triggers, allowing polyethylene molecules to form strong covalent bonds between chains.

The peroxide method has made PEX-A pipe, resulting in superior flexibility, durability, and resistance to stress cracking. This has made it the least likely to crack due to freezing. PEX-A pipes also have a good thermal memory that makes them resistant to kinking most of the time, and even under rare instances of a kink, it could be easily repaired with a heat gun. Moreover, the highest degree of cross-linking throughout the PEX-A pipe has helped provide a more consistent performance tubing system.

What to know about PEX-B

PEX-B pipe is probably the most common PEX pipe type used in the USA, and it is widely manufactured by many companies, including EFIELD. PEX-B pipes are produced using the silane (also known as moisture cure) method. The manufacturing process aims to link the molecules of the HDPE polymer by using a catalyst to expose PEX tubing to moisture (steam bath) after the extrusion process.

PEX-B pipes are typically cheaper than PEX-A pipes, which makes them more budget-friendly. Compared to PEX-A, the installation tools required for PEX-B are generally limited to crimp rings or clinch clamps for connections, with no essential need for expansion tools. This has made PEX-B an ideal solution for DIY lovers, as not too many complicated techniques are required. Pex-B tubings also have a higher bust pressure and the highest chlorine resistance rating. Although we recommend keeping any types of PEX tubing away from sunlight if possible, PEX-B is capable of being exposed to UV light longer than the other types of PEX pipes. But keep in mind that prolonged sunlight will eventually cause the pipes to burst.

PEX-B pipes have a lower degree of cross-linking compared with PEX-A ones, which reflects on their performance as being less flexible and durable. Unlike PEX-A pipes, PEX-B ones tend to be less consistent as they don’t have a uniform cross-linking throughout the pipe. This property raises the possibility of PEX-B pipes leaking and damaging from freezing. PEX-B pipes are not as elastic as PEX-A pipes. The kinks are actually not repairable on PEX-B pipes; the replacement of the affection must be re-installed.

What to know about PEX-C

PEX-C pipes are manufactured using electronic irradiation, also known as the electron beam method. Unlike PEX-A and PEX-B, the cross-linking of the molecules is done after the excursion process. The polyethylene within PEX-C pipes is exposed to high-energy radiation that breaks the existing links between molecules and initiates the cross-linking process.

PEX-C tubing is the stiffest of the three types of PEX, making it the best option for straight runs where minimal bending is required. One of the most significant features of PEX-C pipe is that its production is the most eco-friendly of all three types.

PEX-C pipes have a moderate level of flexibility and durability. The installation tools for PEX-C tubing are limited to only essential clinch or crimp systems, but additional fittings could be required due to its limitation to be bent. They are also less reliable in extreme weather than the other types.

Which PEX tubing to choose?

There are no strict guidelines for which PEX pipe to use. Pex-A, B, or C share some similarities and differences, so your selection will likely be based mainly on your requirements with one of them, such as your budget, pipe availability, and previous experience with piping.

In general, PEX-A is the most flexible of all PEX tubing types; it is repairable for kinks and performs the best under extreme weather. The highest flexibility allows it to have the tightest bend radius to minimize the usage of fittings when a change in direction is required. The larger-diameter expansion fittings could also be used with PEX-A tubing because of its elasticity. It has also been used for the longest time, for over 50 years. However, PEX-A pipe is the most expansive one compared with the other two types of PEX tubing.

PEX-B clearly wins when considering the price compared with PEX-A and PEX-C. It has also been used for over 40 years now. PEX-B and PEX-A tubing share lots of similarities and advantages, while the notable downside of PEX-B is different from PEX-A. One of its main disadvantages is its stiffness. This has made the PEX-B types hard to bend and unrepairable for existing kinks. They are also not recommended to be expanded for special fittings.

PEX-C is the vaguest of the three PEX tubing types to evaluate. Although it shares benefits and drawbacks with PEX-B and PEX-C, it doesn’t make a good combination of these two types stand out. We recommend considering PEX-A and PEX-B tubing primarily.

No matter which PEX pipe you choose, you are guaranteed to save project costs and labor compared with other types of piping systems. You will also expand the lifespan of your piping system with less maintenance required or problems occurring.

About EFIELD® PEX Pipe

EFIELD PEX-A and PEX-B pipes are available at PlumbingSell at great prices and fast delivery. These chlorine-resistant pipes are approved for use in portable water installations. We also offer various pipe sizes and PEX fittings to best suit your needs.

No minimum order for delivery is required. For more information on EFIELD PEX pipe, check out our product page here.